Industrial Insulation: Efficiency, Safety, and Sustainability

Industrial Insulation: Efficiency, Safety, and Sustainability

In industry, where every detail can make the difference between an efficient process and one with constant losses, insulation plays a crucial role. It’s not just a coating on pipes or equipment; it is a technical solution that allows optimizing energy, protecting staff, and extending the life of installations.

What It Is and Why It Is Necessary

Industrial insulation involves thermally insulating pipes, tanks, and industrial equipment using materials with low thermal conductivity. With this, three main objectives are achieved: reducing heat losses and, therefore, energy consumption; protecting people from contact with surfaces that are too hot; and ensuring that production processes remain within optimal temperature conditions.

According to a study by the Insulation Institute, a good insulation system can reduce energy consumption in certain installations by between 10% and 40%, as well as limit the associated CO₂ emissions.

Technical Criteria for Defining Thickness

The thickness of insulation is not an arbitrary value. It is calculated based on two main factors: the diameter of the pipe or equipment and the design temperature. The larger the diameter and the higher the temperature, the thicker the insulation required to achieve the same level of protection.

This allows for the differentiation of two clear applications: when the goal is to conserve heat, thicker insulation is required to avoid energy losses; on the other hand, if the goal is simply to protect personnel, a thinner layer may suffice, enough to keep the external surface below 60°C. According to the BS 5422:2009 standard, often used as a reference in many European projects, these variables are key in setting design tables.

Common Materiales abd Coatings

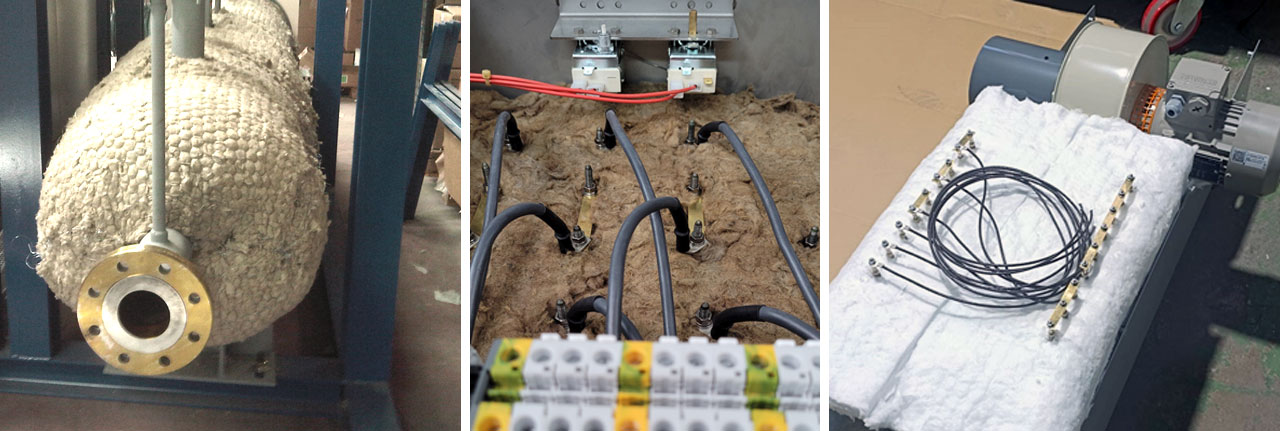

The most commonly used material in industrial insulation is rock wool with a density of around 100 kg/m³. Its thermal resistance, mechanical stability, and durability make it an ideal option for pipes and large equipment. Furthermore, it can tolerate very high temperatures without losing performance and is fire-resistant, a valuable feature in critical environments.

However, there are also other options depending on the application: ceramic fibers for extreme temperatures, rigid foams for areas requiring lightweight insulation, or elastomeric materials for applications where flexibility is a key factor.

To protect this insulation and ensure its durability, it is common to cover it with a stainless-steel sheet, which acts as a barrier against moisture, corrosion, and impact. In other environments, aluminum sheets or special coatings are also used according to the chemical requirements of each installation

Benefits of Insulation

Benefits of Insulation

The advantages of having a good insulation system can be summarized in four major areas:

- Energy Efficiency and Savings: Reducing heat loss means less consumption and lower bills. According to the European Industrial Insulation Foundation (EiiF), the potential for energy savings in Europe through thermal insulation improvements is enormous, with quick and tangible returns on investment.

- Workplace Safety: Keeping the surface temperature of installations at safe values prevents burns and accidents, improving working conditions and complying with risk prevention regulations.

- Equipment Durability: Sudden temperature changes, condensation, and corrosion are factors that deteriorate materials. Proper insulation minimizes these risks, extending the lifespan of installations.

- Contribution to Sustainability: Reducing energy consumption means lowering greenhouse gas emissions and moving towards global climate goals.

Best Installation Practices

An insulation system is only effective if installed correctly. Some recommended best practices are:

- Size the thickness according to recognized standards (e.g., BS 5422 or ISO equivalents).

- Ensure professional assembly, avoiding poorly sealed joints or uncovered areas.

- Cover with materials resistant to the environment where the installation is located.

- Periodically check the condition of the insulation to detect possible damage and repair it in time.

Conclusion

Insulation is not a secondary addition but a technical necessity in any industrial plant. Its correct application represents measurable energy savings, improves safety, and contributes to sustainability goals.

At IES Soler, we work with high-quality materials such as rock wool and metallic coatings, applying over 80 years of engineering experience to design insulation projects tailored to each need.

Do you want to optimize the performance and security of your equipment?

Contact our technical team, who will advise you on the best thermal insulation solution for your project.